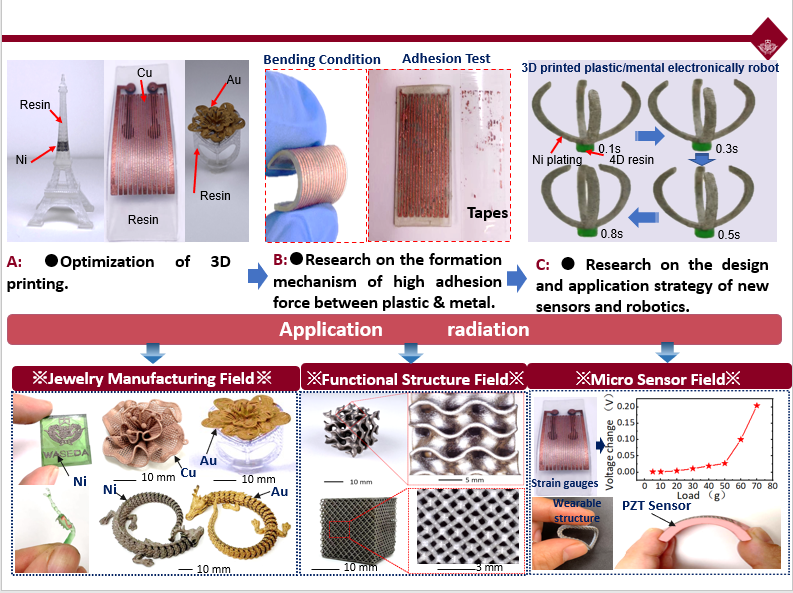

Building precise metal patterns on complex three-dimensional (3D) plastic parts allows for the manufacture of functional devices for advanced applications. However, it is currently expensive and requires complex processes. To address these issues, our lab is developing a technique to fabricate 3D metal-plastic composite structures with arbitrarily complex shapes. The cured resin is modified to prepare an active precursor for subsequent chemical plating (ELP). The newly developed multi-material digital light processing 3D printer is used to manufacture parts that contain interlocking nested regions made of standard resins or active precursors. Using this technology, 3D devices that cannot be manufactured by conventional methods are possible and metallic patterns can be created inside plastic parts as a means of further miniaturizing electronics and significantly reducing production costs.