Category: Metal-Plastic Hybrid 3D Printer

-

Reinforcement Layers Built with Multi-Degree-Of-Freedom Material Extrusion Additive Manufacturing Achieve Strength Enhancement

To improve weak interlayer bonding in material extrusion, we propose a six-axis printing strategy with designed core and reinforcement layers. Mechanical tests and SEM analysis confirm that adjusting layer ratio, raster angle, and fill rate significantly enhances strength. http://dx.doi.org/10.2139/ssrn.4798414

-

Complex architecture fabrication with photosensitive PEEK-based ink via vat photopolymerization and two-step thermal treatment

This study presents a photosensitive PEEK-based ink for vat photopolymerization, enabling high-resolution printing and improved performance via two-step thermal treatment. Optimized for printability, crystallinity, and material properties, the method enhances PEEK’s thermal, mechanical, and corrosion resistance, expanding its application potential beyond extrusion-based limitations. https://doi.org/10.1016/j.addma.2025.104840

-

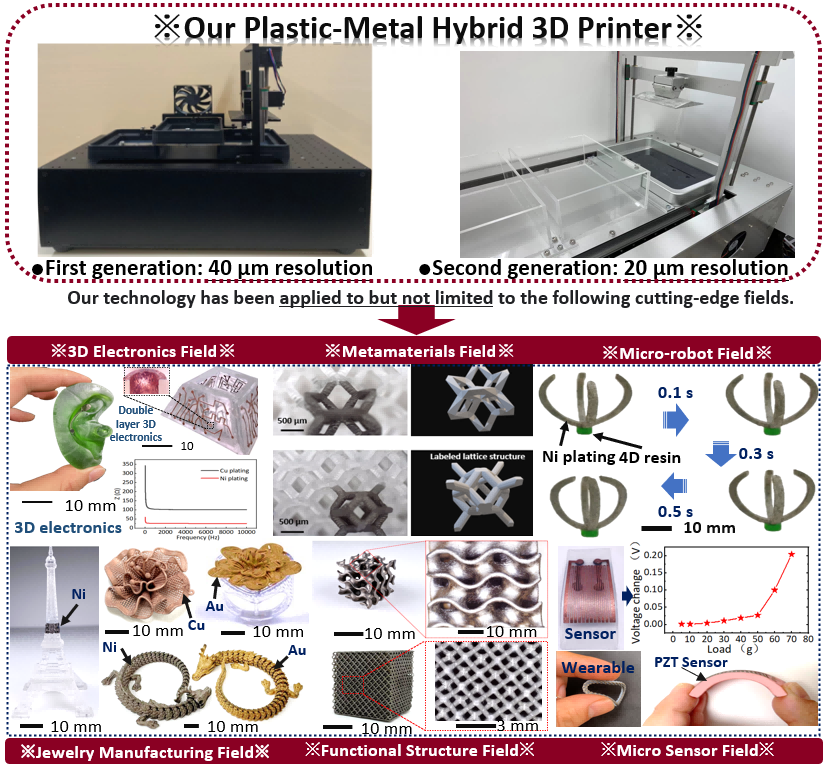

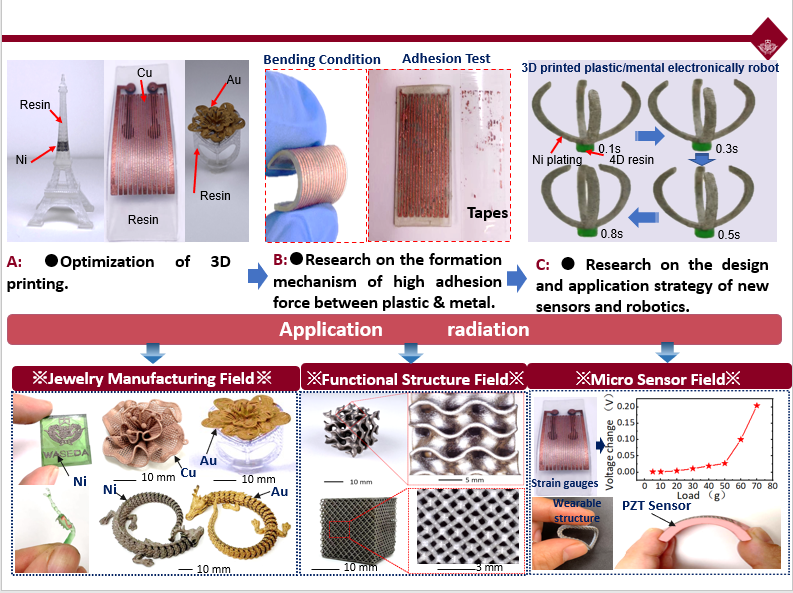

Multi-material 3D printing technology: integrated preparation of polymers and metals

Existing three-dimensional (3D) printing technologies, both polymer-based and metal-based, can only fabricate (only) plastic structures or (only) metal structures, which severely limits the application of additive manufacturing technologies in electronics such as IOT, ICT and robotics. Electronic devices are usually composed of both functional plastics and metals, including sensors and micro-actuators. They are connected together…

-

New Metal-Plastic Hybrid 3D Printer for electronic miniaturization

Building precise metal patterns on complex three-dimensional (3D) plastic parts allows for the manufacture of functional devices for advanced applications. However, it is currently expensive and requires complex processes. To address these issues, our lab is developing a technique to fabricate 3D metal-plastic composite structures with arbitrarily complex shapes. The cured resin is modified to…